Atalanta: Refitting a Modern Classic - Part 1 of 3

Among the wind-swept cypress trees and sprawling golf courses of the Monterey Peninsula, where classic and exotic car enthusiasts gather each year for the famed Concours d’Elegance, it is often said that there is nothing more expensive than a cheap Ferrari. When my boat partner Chuck and I upgraded from our Santana 35 and bought Atalanta, a custom 1988 New Zealand-built Farr 53 in the summer of 2020, although she looked beautiful, we knew we were in for a project.

The first day I saw her, she was sitting somewhat forlornly in her slip, but I instantly recognized the potential

I had spent the first part of the pandemic reinventing myself. After racing yachts in the Med and Caribbean for most of my 20s, I had a two-decade long career as a nonprofit fundraiser. During the early days of the pandemic, I realized that where I was happiest was on the water. Inspired by offshore sailing programs like 59 North, my goal was to start a business that combined offshore passages with local charters on Monterey Bay. I passed my 100-ton Coast Guard license and set off to find the perfect boat. Unfortunately, most boats were either out of my geographic area or out of my budget, or otherwise not suitable for offshore charters. High on my wish list were individual berths, rather than the double cabins found on many modern boats. When Atalanta was listed right in our backyard, we immediately went to see her.

Her gorgeous Tawa interior concealed some major issues lurking below the floorboards

The boat showed beautifully on that summer day on San Francisco Bay, and the immaculately varnished Tawa interior, a light hardwood native to New Zealand, glowed alluringly in the morning sun. The 130hp Volvo diesel had been completely rebuilt and had only 2900 original hours. She ticked all of our boxes. Her lines, to my eye, were perfect. The boat had a presence about her that was undeniable.

A scale model in the St. Francis Yacht Club offered a peek of what she could be once again

Elsewhere, however, things were not so rosy. An aging teak deck, original 80s vintage electronics, frayed running rigging and pools of hydraulic oil gave glimpses of some of the major projects we would need to undertake. But the price was too good to pass up, and we knew that this would make a comfortable and safe cruising platform for our families and friends. Additionally, it would enable me to realize my dream of offering charters on the West Coast and beyond. Needless to say, we took the plunge without hesitation. We immediately enlisted Gilles Combrisson of GC Rigging and Composites, who had worked on our previous boats, to oversee the refit and moved the boat to the Sugar Dock in Richmond, California.

The list was long and daunting, but Gilles and his team tore right in.

The refit started with a full overhaul of the Navtec hydraulics

Badly corroded inner stay hydraulic ram housing

Neglected mast jack

Our first project was to service all of the hydraulic systems on deck. Like many boats of that vintage and size, hydraulics were used on many of the rigging adjustments and we found no fewer than 7 cylinders that needed overhauling: outhaul, vang, backstay (x2), inner forestay, baby stay and a pleasant surprise when we removed the mast, a mast jack to release tension on the rig for easy shroud adjustments. All of the Navtec components were original but fortunately replacement seals and other parts were not difficult to come by.

Half a kilometer of 14mm Dyneema

New running backstays, checkstays and 2:1 main halyard ready for installation

New spinnaker and jib halyards

Next, all of the running rigging was due for replacement, so we ordered a half kilometer of 14mm Dyneema, which was necessarily oversized to work properly in the self-tailers of the old style Lewmar 65 electric primary winches, which were not in the budget to replace. Kaya Ropes represented a good value compared to name brands and we have been very pleased with their performance and durability. We upgraded the main halyard to 2:1.

New sails were also not in the budget, but Gilles built a new inner forestay out of PBO and David Hodges at Ullman Sails Santa Cruz converted a #5 jib from a Santa Cruz 70 to a full-sized staysail, adding soft hanks to the luff. David also converted a #5 jib from a Sydney 38 to a storm staysail using the same hank system, and he recut a Santa Cruz 70 spinnaker into an asymmetric cruising chute with an ATN sock for shorthanded sail handling. These modifications were very budget-friendly.

Full sized staysail: a converted Santa Cruz 70 #5 jib with Dyneema soft hanks on a PBO inner stay

Storm staysail: a converted Sydney 38 #5 jib

Asymmetric spinnaker: ATN sock added to a recut Santa Cruz 70 spinnaker

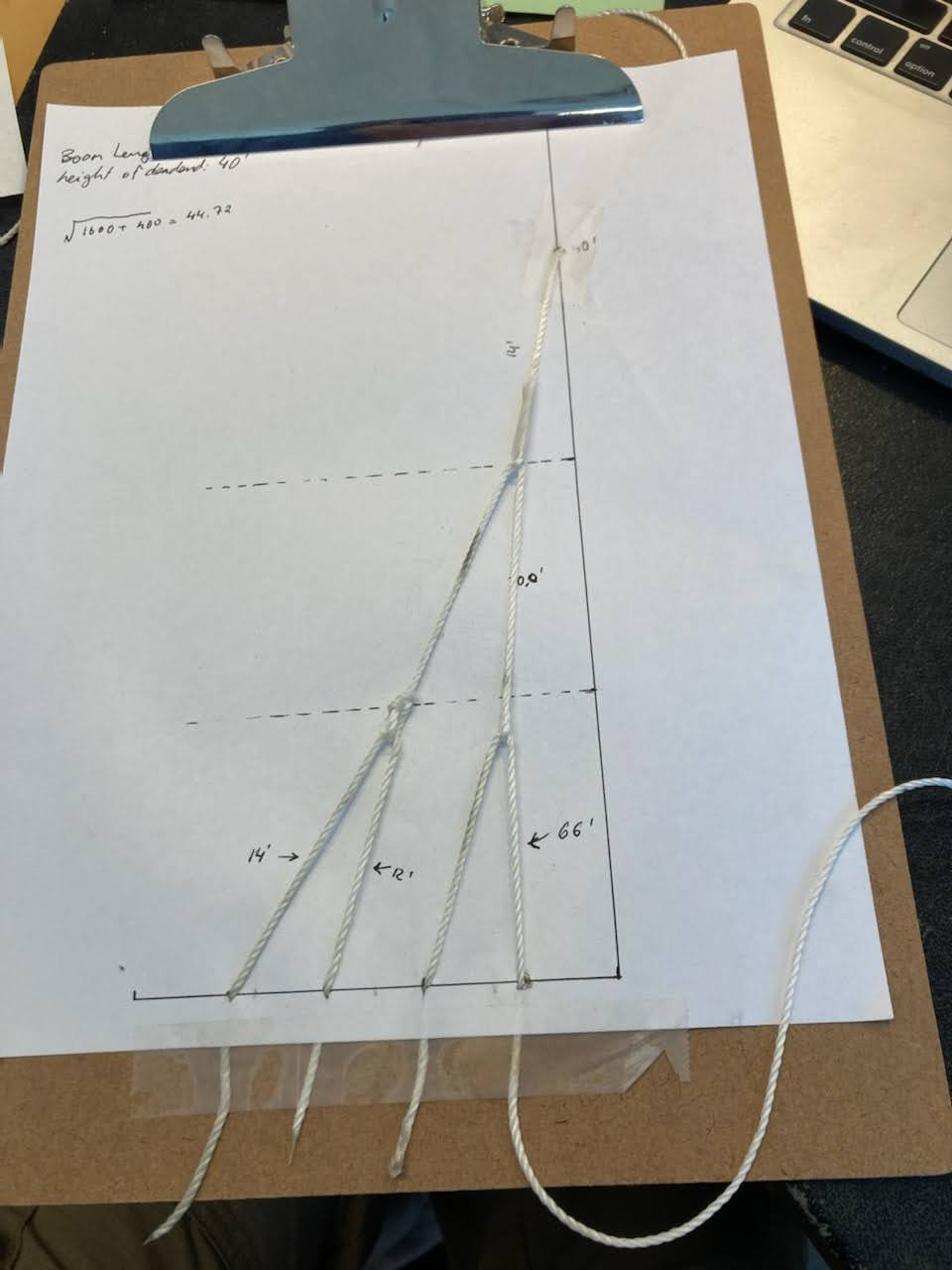

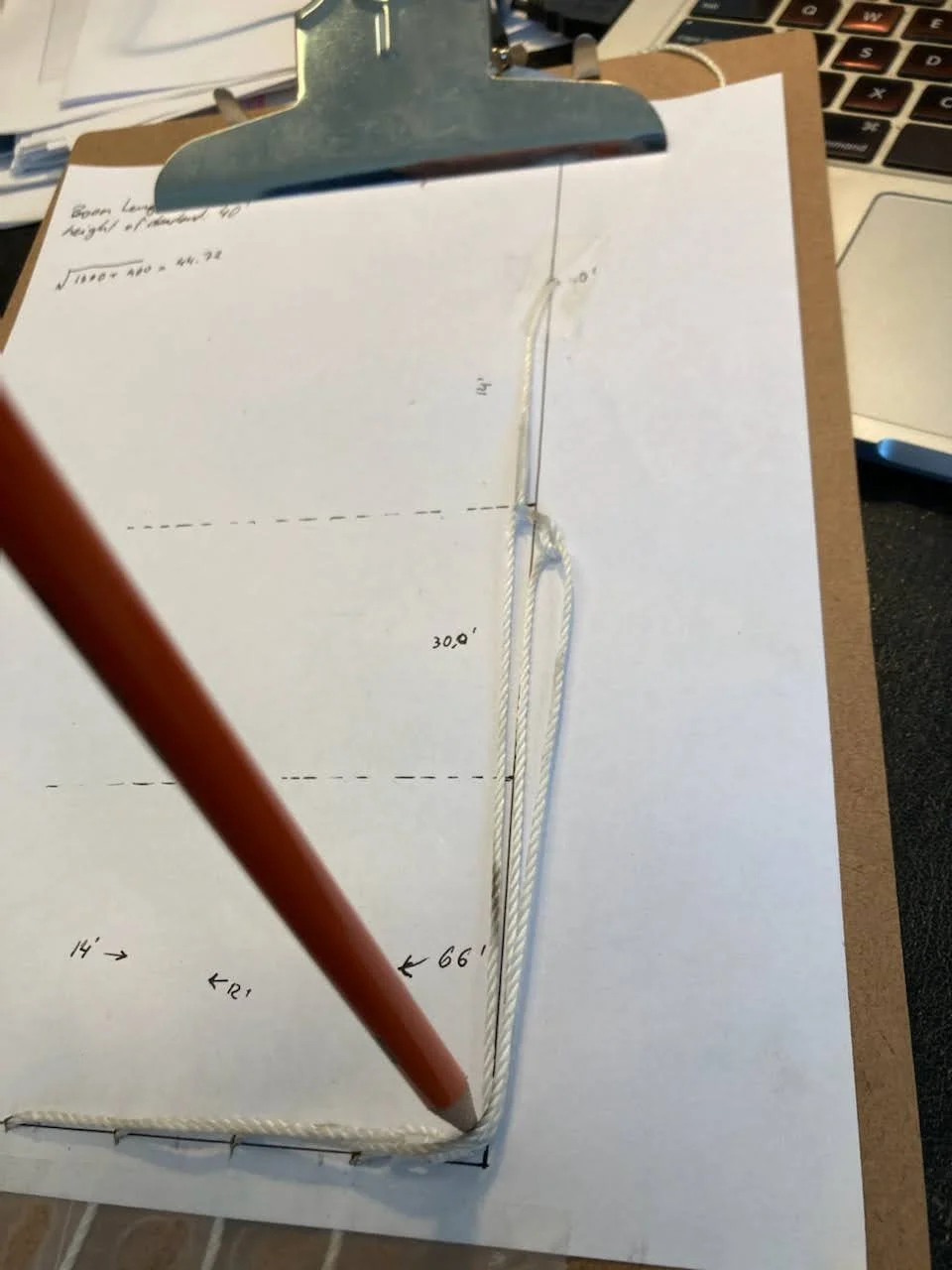

A clever upgrade was Gilles’ design and installation of a lazy jack system that would work with a conventional sail cover. Instead of running the lazy jacks through a block on the mast and down to a cleat, which can cause them to slap against the mast, Gilles designed them to dead-end at the top and then be adjustable at the boom, with enough extra line that they can be run forward completely to be stowed out of the way – very clean.

Dyneema lazy jacks design

With ability to be run forward

Lazy jacks work exactly as designed

When we later decided that we would be better served by a stack pack, the lazy jacks were removed from the boom and attached to the stack pack, requiring no further modifications. Mark Gibbs at Monterey Bay Canvas took the sail cover and because the Sunbrella material was new, simply cut the top open, added a zipper, inserted some battens, and used the bolt rope track on the boom that had originally worked with a close-footed main to hold the stack pack in place on the boom. This was a very cost-effective alternative to having a new stack pack built and it functions beautifully, especially on charters with limited crew.

Sail cover eventually converted to a stack pack, with the lazy jack attachments moving from the boom up to the battens

Zipper system for ease of sail handling

We also felt it prudent to replace the lifelines and gates all around, using new wire, fittings and quick-attach pelican hooks. This gave us the opportunity to dispose of the old lifelines with plastic coatings, which can trap moisture and weaken the fittings while at the same time making them difficult to inspect. Notably absent on the boat were mooring cleats, so Gilles mounted those aft and amidships, incorporating beautifully finished G10 backing plates for each.

Rig out

Next month in Part 2, we pull the mast, have an offshore dodger designed and built, replace cabin windows (and what lurks behind them), rebuild a compass, replace our electronics, and revamp the entire electrical system. Stay tuned!