Steering Us Straight

Greater than 200lbs.

Less than 75lbs.

That is the difference between a 1988 designed rudder made of fiberglass, wood and stainless steel, and a 2024 designed rudder made of closed cell foam and resin pre-impregnated carbon fiber. The stark contrast in weight is indicative of the improvement in all aspects of the new foil. Here is how it happened.

Original rudder looked ok on the surface

For those of you who followed Atalanta’s major refit in 2020-2021, you will recall that the rudder bearing was completely frozen and had to be replaced. I won’t go back into those details, but this is what we found when we tried to remove the rudder in 2021:

Frozen solid

Cracks - not good!

Significant surgery required

Once we finally had the rudder out and completed our plans to install new bearings, we found the rudder itself had water ingress but was otherwise sound. So, we made the decision to dry it out, patch it up, and put it back into service.

Original rudder getting some TLC at GC Marine

That was fine, except that the rudder over time had developed an asymmetry, which meant that the blade created more lift on one side than the other. This made the boat always turn left regardless of the wind angle or wind strength. Besides being annoying, it also put an unnecessary load on the autopilot on port tack, and the helm was alarmingly neutral on starboard.

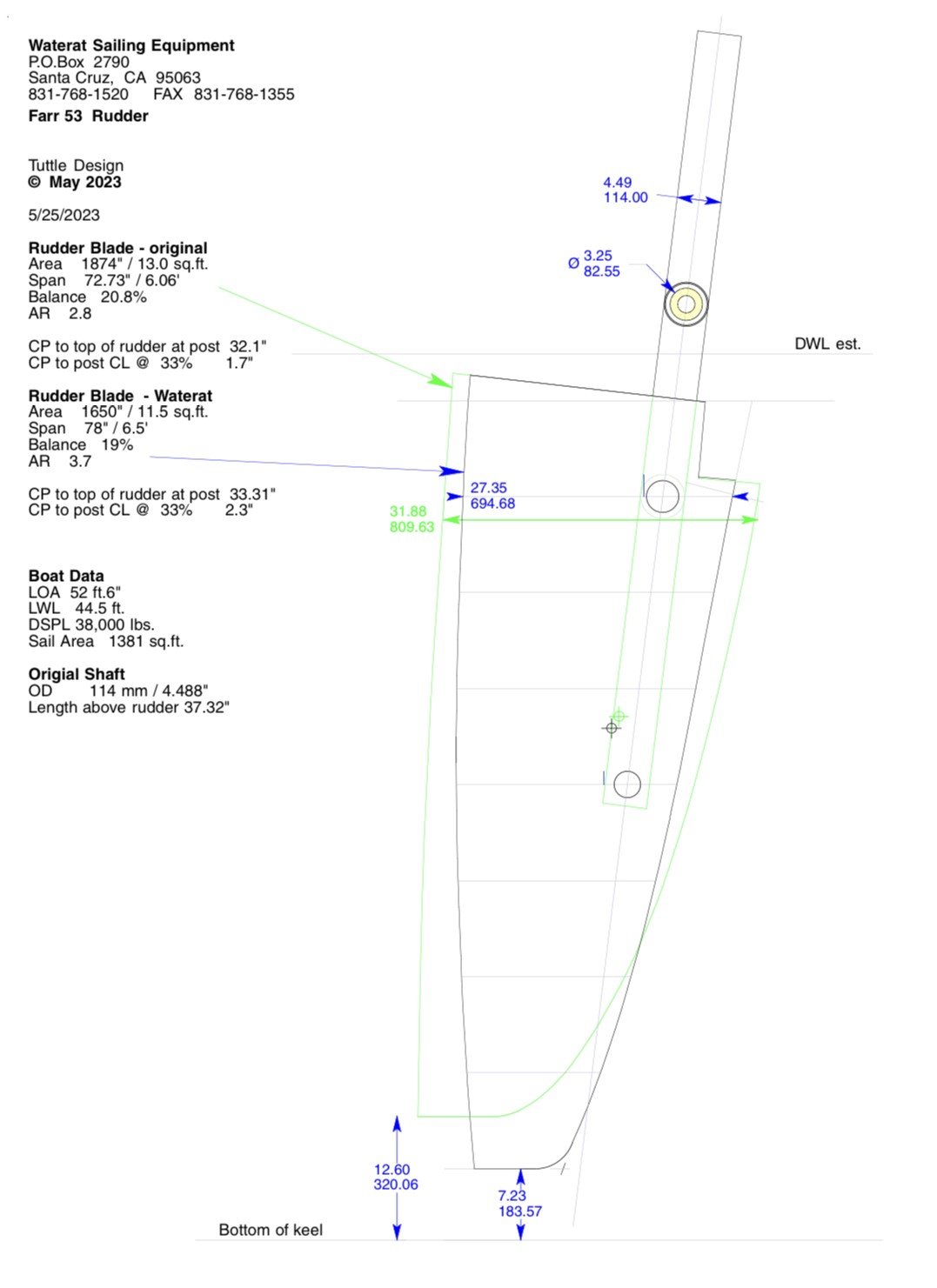

We discussed the possibilities of fairing the rudder but quickly decided that since rudders do not last forever, this one had served its purpose and was due for replacing. Enter Larry Tuttle at Waterat Sailing Equipment in La Selva Beach, California. Known worldwide for his beautifully crafted carbon rudders for everything from dinghies to large ocean racing yachts, Larry drew a new foil that he promised would make a significant difference in the boat’s performance. He did not disappoint.

A tale of two foils

Larry Tuttle (left) discussing details of the new carbon rudder shaft

Bringing home the goods

After months in design and production, the rudder was finally complete in February of this year. To geek out for a moment, highlights were: 10% reduction in wetted surface area; shorter cord length; deeper draft; weight savings; better balancing; and increased stiffness and reduced drag especially in the lower half of the foil.

In March, master rigger and composites guru Gilles Combrisson of GC Rigging and Composites, who managed Atalanta’s major refit, came to Monterey to do the installation at Monterey Bay Boatworks.

Side by side

Rudder art

Final fitting

Quadrant reassembly

Thanks to meticulous preparation by Gilles and Larry, the rudder went in without a hitch. We took the opportunity to fully service the steering system including cables and quadrant before reassembly. Launching the boat after a brief two-week stay in the boatyard was a relief to say the least. It was great to have this major project finally behind us.

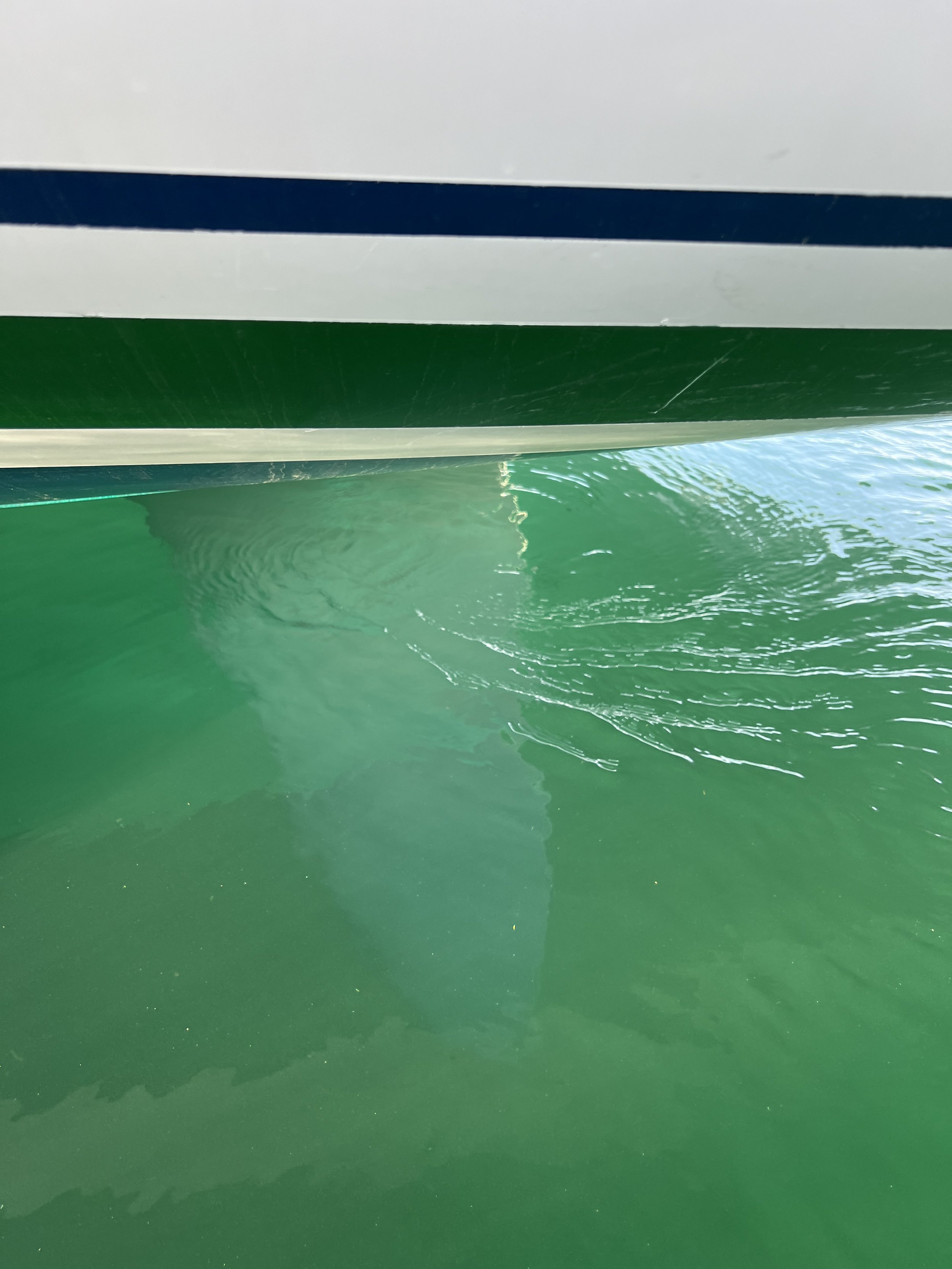

Once the rudder was in, it was time for a sea trial. Suffice to say, the buttery smooth feel and fingertip control made Atalanta behave like a whole new boat. No more left turn, no more heavy helm feel, just a sure and immediate response to the slightest wheel adjustments. And with full main and jib in 20 knots of wind on a close reach, there was not the slightest hint of a stall or being overpowered, which made the autopilot easily able to handle the loads even at 25 degrees of heel or more.

New blade at work

Sea trial success!

This upgrade is clearly an improvement for Atalanta’s performance, but more importantly, it provides increased confidence in the boat’s ability to handle anything the wide Pacific can throw at her.

Rudder failures are not uncommon on ocean crossings, and with this improvement in both design and materials, the boat is ready for extended blue water voyaging. Where do you dream of pointing the bow? Regardless, Atalanta is up to the task.